The components of new energy vehicles can be produced through five axis machining. For new energy vehicles, large structural parts of the integrated die-casting body, such as the body frame, need to be processed after molding. Five axis machine tools can perform high-precision and complex contour machining on these large integrated die-casting parts, including multiple processes such as cutting, drilling, milling, etc., thereby improving the accuracy and surface quality of the parts.

With the development of science and technology, the 3C industry (computer, communication, and consumer electronics) has become one of the most important industries today. Emerging consumer electronics products represented by mobile phones, tablets, wearable devices, etc. are growing rapidly. The application of 5G is an important transformation in the smartphone industry. 5G smartphones have higher requirements for chip processing capabilities, battery technology, heat dissipation, and more. Testing and assembly equipment needs to be upgraded or replaced. The 3C automation equipment industry has good development prospects.

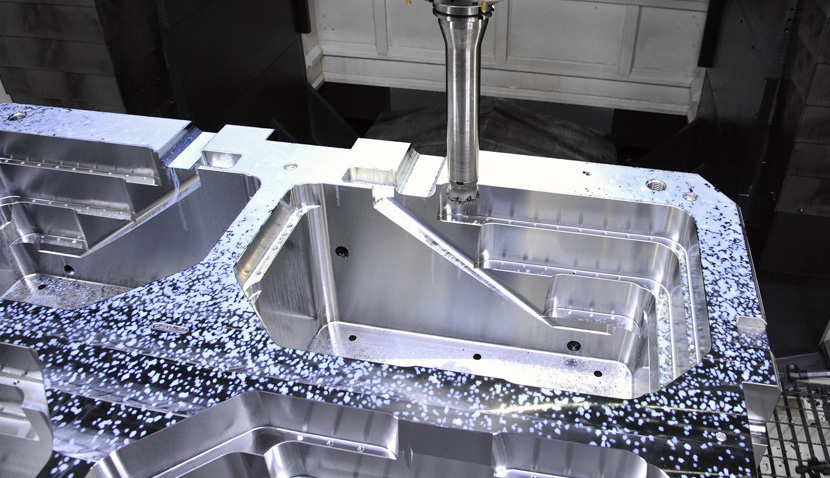

With the continuous expansion of mold applications, higher requirements have been put forward for mold manufacturing, which has made the development speed of the mold industry faster than that of other manufacturing industries a universal law. Mold processing requires precise specifications and high precision to achieve accurate part dimensions, complete structure, and consistent shrinkage dimensions of each cavity.

With the rapid development of the aerospace industry, the demand for high-precision and high-performance components is increasing day by day. The modern aerospace field has very high requirements for components, requiring precision machining and complex construction. The development of the aerospace industry in various countries has put forward higher requirements for the mechanical processing industry, becoming an important driving force for promoting industry development.

Efficient processing of engineering machinery parts helps precision manufacturing enterprises improve quality and efficiency. The machining accuracy of mechanical parts directly affects the service life and safety of products. When machining parts, it is necessary to strictly follow the design requirements to ensure that the machining accuracy meets the requirements. Before processing, it is necessary to carefully analyze the processing diagram and develop a reasonable processing technology flow to avoid processing errors.