The Tianying R&D team is composed of about 20 professional talents, mainly engaged in specialized research and development, production process optimization, product performance testing, and application development of cutting-edge technologies, high-end machine tools, core components, and system development. They gather expert teams in the industry to collide technologies and solve bottleneck problems in the machine tool industry and high-end equipment research and development, achieving self-made core components such as spindles, precision turntables, and power tool towers.

Global high-precision and high-precision grinding machines, high-end machining mother machines

Standardization of incoming material quality control: traceability of raw material and component sources Standardization of production process: Combining product structure and design standards, each part has a machining process card, and each unit has an assembly process card Standardization of production quality control: According to the standardized operation system, the entire production process is strictly completed and inspected according to the process card standards to ensure that every product has excellent quality Product production history can be traced: data is retained for each production process, and each machine's production can be traced

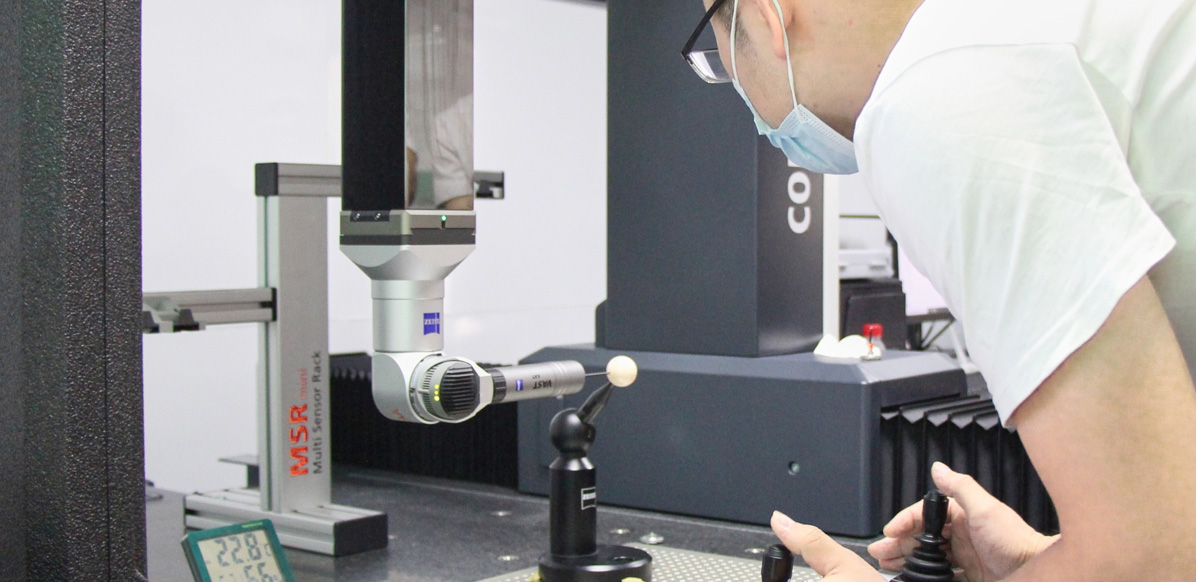

Strict quality control is implemented throughout the entire process from design, procurement, processing, production, inspection, testing, packaging, transportation to customer service, ensuring that every link, step, and detail has strict control and digital records, traceable sources, and searchable information. The quality center is equipped with precision measuring instruments such as coordinate measuring instruments, laser interferometers, ball bar detectors, dynamic balance detectors, vibration analysis, etc., providing guarantees for the high precision, high yield, and high reliability of CNC machine tools.