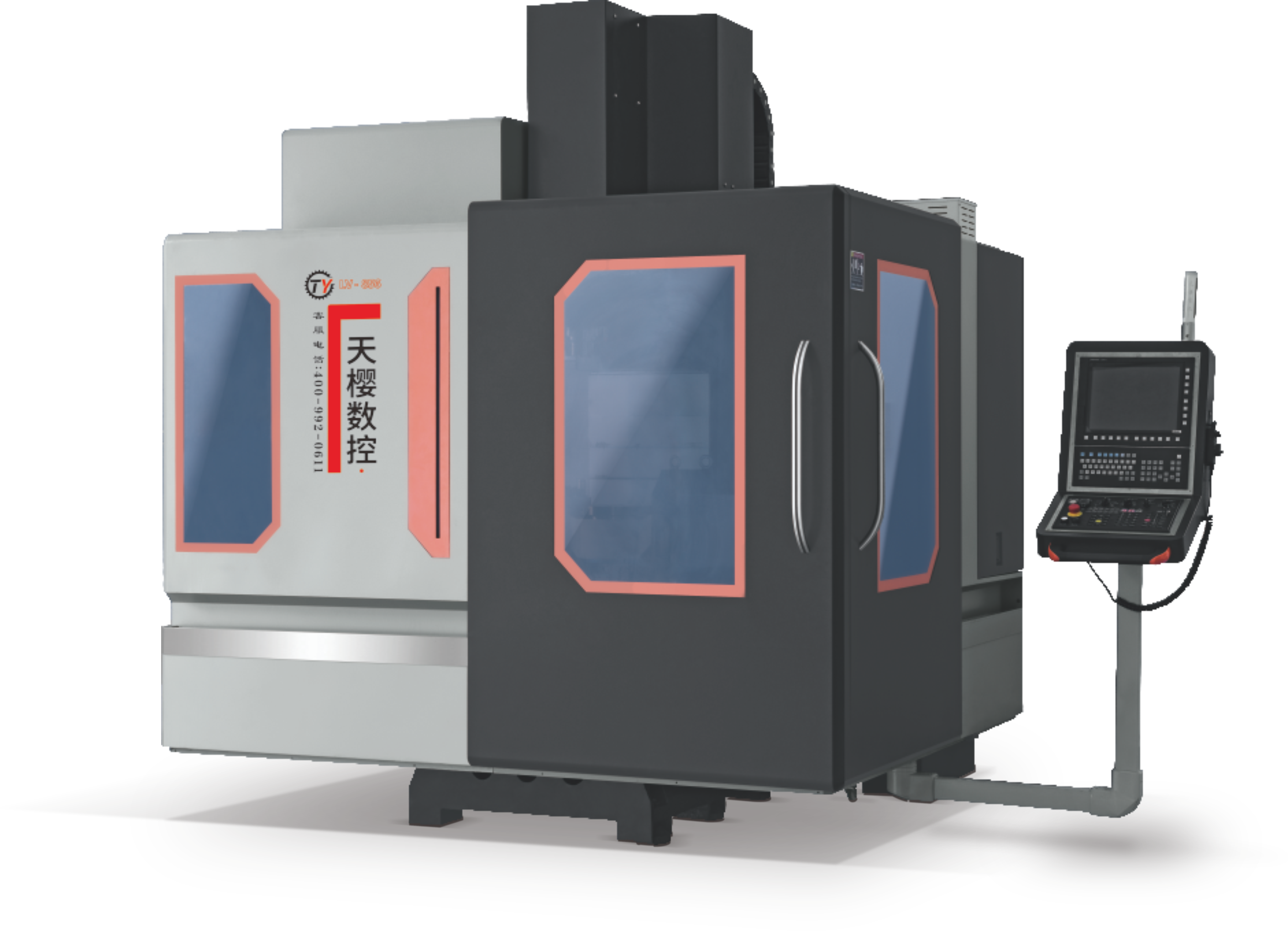

The best bed structure design can withstand the inertia generated by high G, and is as solid as a rock and as stable asMount Tai.

The short nose spindle has excellent rigidity, which improves efficiency and reduces tool wear.The three-axis rapid displacement greatly shortens the processing time.

The high-stability tool change system reduces non-processing time.

The rear chip removal structure is adopted, which is convenient for cleaning waste chips and not easy to leak oil.All three axes are supported by high-rigidity linear rails, with fast speed and high precision.

| Name | unit | V-8 | V-866 | V-1165 | R em a r k | |

| Processing range | Worktable travel(X axis) | mm | 800 | 800 | 1100 | |

| Saddle travel(Y axis) | mm | 500 | 600 | 650 | ||

| Spindle box travel(Z axis) | mm | 500 | 600 | 650 | ||

| Distance from spindle nose to work table | mm | 90-630 | 110-680 | 100-730 | ||

| Distance from spindle center to column guide surface | mm | 580 | 600 | 600 | ||

Workbench | Workbench size | mm | 1000×500 | 1000×550 | 1200×650 | |

| Workbench load-bearing | kg | 500 | 500 | 800 | ||

| T-slot(number of slots-slot width'spacing) | mm | 5*18*84 | 5*18*72 | 5*18*120 | ||

Spindle | Recommended motor power | kw | 7.5/11 | 11 | 11 | |

| Spindle speed | rpm | 12000 | 12000 | 8000 | ||

| Spindle diameter | Mm | φ140 | φ150 | 中150 | ||

| Spindle taper | / | Bt40 | Bt40 | Bt40 | ||

Speed | Cutting feed speed range | mm/min | 1-10000 | 1-10000 | 1-10000 | |

| X/N/Z axis fast moving speed | m/min | 48/48/48 | 36/36/36 | 24/24/24 | ||

| Tool magazine | Tool magazine capacity | Bundle | 24 | 24 | 24 | |

| size | Approximate machine tool dimensions (length"width"height) | mm | 2400*2150*2500 | 2600*2500*2600 | 3200*2700*2900 |