1.Processing complex surfaces: The five-axis machining center is specially used for processing complex surfaces, and is suitable forprocessing impellers, blades, marine propellers, and other complex parts.

2.High precision: The five-axis machining center performs dimensional analysis through five-axis positioning to achieve high-precisionmachining.

3.High efficiency: The productivity of the five-axs machining center is generally 3 to 5 times that of the ordinary machining center, whichcan cope with the processing of complex parts and improve production efficiency.

4.Flexibility. The five-axis machining center only needs to change the CNC sequence when processing object conversion,showing goodadaptability, which can save a lot of time for production.

5.High flexibility: The five-axis machining center can form an automated production system with high flexibility

6.Good production conditions: The machine has a high degree of automation, the operator's work intensity is greatly reduced, and theworking environment is better.

7.Favorable management:The use of a five-axis machining center is conducive to the mastery and management of production, creatingconditions for the automation of the production process.

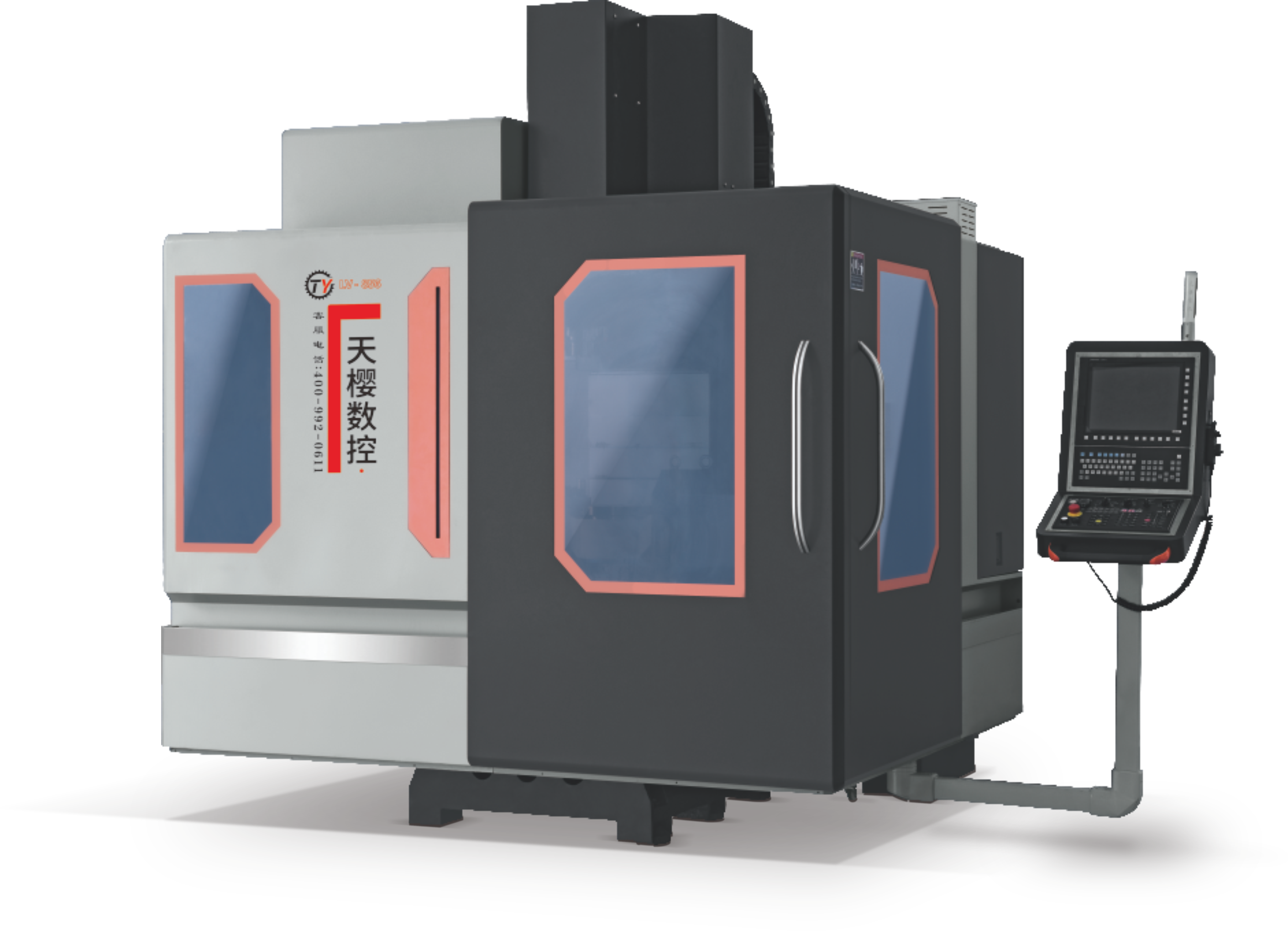

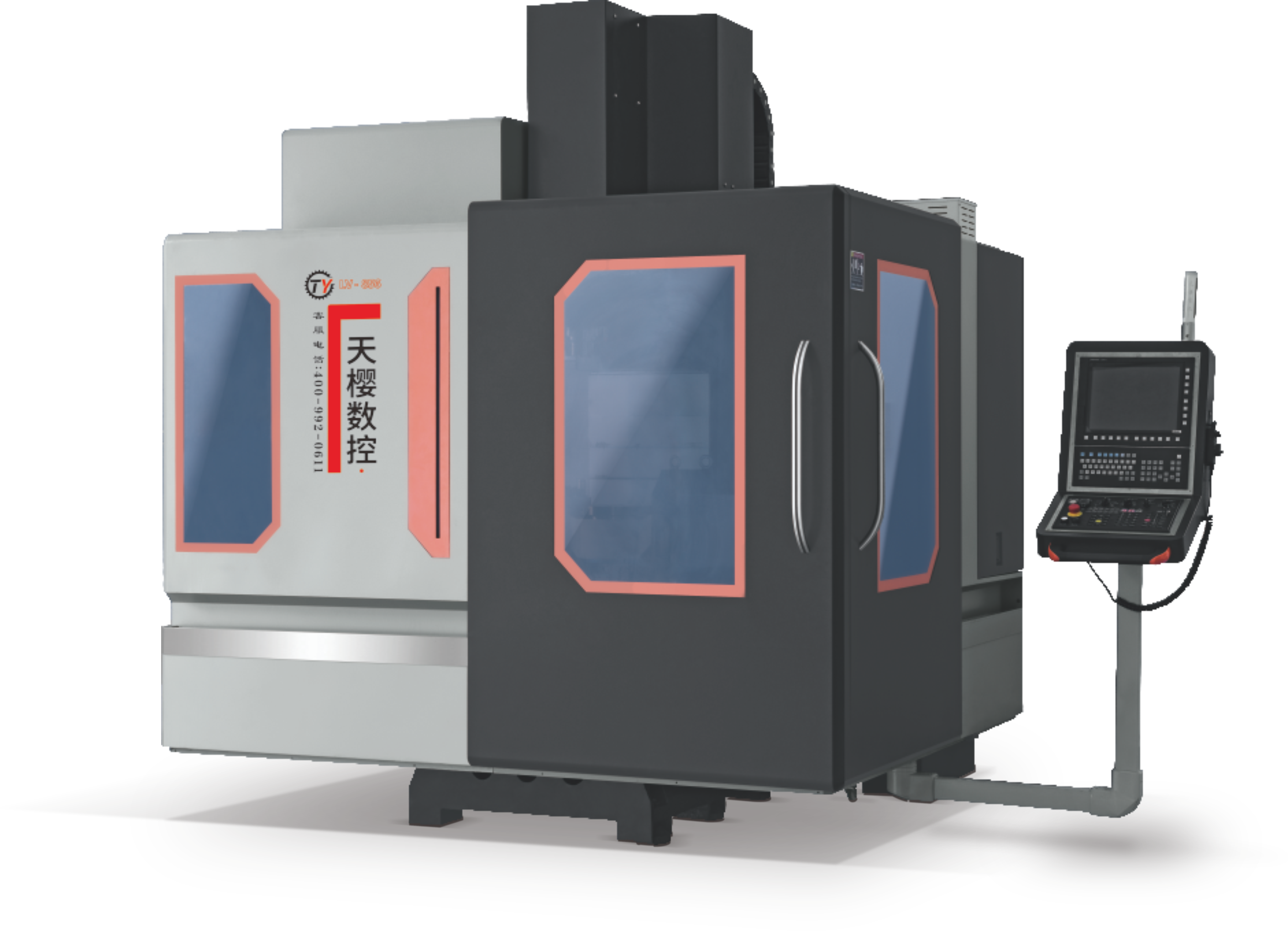

| project | LV-856Vertical five-axis machining center |

| Three-axis travel | XYZ:800*550+600mm |

| Workbench size | 0260/0320 |

| Spindle specifications | BT40-0 150 Long Nose Direct |

| Spindle end to worktable surface | 50-650mm (use 200mm heightening pad) |

| Tool Magazine | BT40-24T |

| Five-axis cradle specifications | DTR260-500 |

| A-axis travel (tilt axis) | ±120° |

| A-axis maximum speed | 189rpm |

| A-axis rated torque | 259N.m |

| A-axis positioning accuracy | ±8 |

| A-axis repeat positioning accuracy | ±5 |

| Caxis travel (tilt axis) | 360° |

| C-axis maximum speed | 386rpm |

| C-axis rated torque | 122N.m |

| C-axis positioning accuracy | ±8 |

| C-axis repeat positioning accuracy | ±5 |

| Braking method | Air brake |

| Machine appearance | 2035/243(T2610(with standard cradle + tool magazine) |