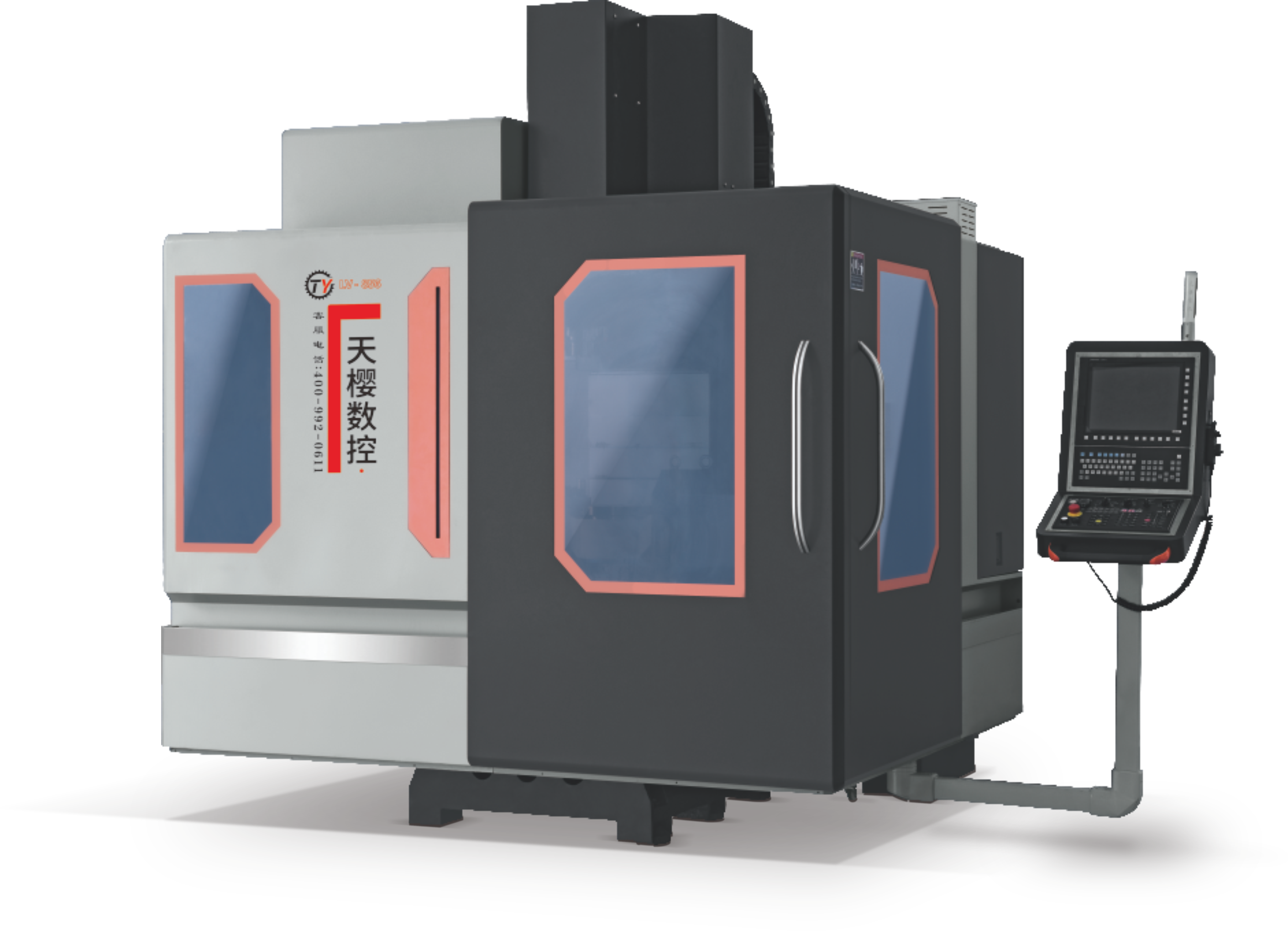

The milling machine tool perfectly combines the CNC lathe milling multi-sided machine tool, and has bothCNC turning and multi-sided forming chip cutting functions. It can complete multiple processes such asturning the outer circle, drilling, cutting and turning the multi-sided at one time.(The product has highconcentricity and one machine has multiple uses).

The milling machine tool adopts the bed and bed foot integrated sanding process, and uses imported rollerlinear rails and lead screws, so it has good shock resistance and strong cutting force.

The milling machine tool can realize spindle positioning according to different products, and can cut anypolygon processing (it can complete irregular shapes such as three-sided, four-sided, five-sided, six-sided,seven-sided, etc. at the same time) lf the milling machine tool does not use the turning polygon function, itcan also be used as a high-precision precision CNC lathe.

| Serial number | Type | Project | CK-52YD |

| 1 | Spindle parameters | Spindle speed range | 0-4000 rpm |

| Spindle through hole diameter | 66 mm | ||

| Diameter of the through hole of the drawn tube | 52 mm | ||

| spindle type | A2-6 | ||

| 2 | Processing range | Maximum rotation diameter on the bed | φ500 mm(depending on the turret) |

| Maximum processing diameter | φ270 mm | ||

| Maximum processing length | 500mm(depending on the turret) | ||

| 3 | X,Z axis parameters | X-axis travel | 260 mm |

| Y-axis travel | ±50 mm(depending on the turret) | ||

| Z-axis travel | 600mm | ||

| Three-axisXYZaxisfast moving speed | 25/15/25m/min | ||

| 5 | 电机功率 Motor power | Spindle motor power | 17 Kw |

| x,Y,Zaxis motor power | 2.4 Kw | ||

| Power head motor power | 2.3KW | ||

| 6 | Power turret | Side power head | BMT55/BMT45 |

| Front power head | BMT55/BMT45 | ||

| Number of tools | 12/15工位12/15Workstation | ||

| Power head speed | 5000 | ||

| 7 | Tailstock | Movement | 100 mm |

| Spindle taper | MT-5 | ||

| tailstock shaft diameter | φ80mm | ||

| Tailstock travel | 400mm | ||

| Tailstock track structure | Linear rail/hard rail |