Professional technical research and development to meet the needs of the market and customers

1.Processing complex surfaces: The five-axis machining center is specially used for processing complex surfaces, and is suitable forprocessing impellers, blades, marine propellers, and other complex parts.

2.High precision: The five-axis machining center performs dimensional analysis through five-axis positioning to achieve high-precisionmachining.

3.High efficiency: The productivity of the five-axs machining center is generally 3 to 5 times that of the ordinary machining center, whichcan cope with the processing of complex parts and improve production efficiency.

4.Flexibility. The five-axis machining center only needs to change the CNC sequence when processing object conversion,showing goodadaptability, which can save a lot of time for production.

5.High flexibility: The five-axis machining center can form an automated production system with high flexibility

6.Good production conditions: The machine has a high degree of automation, the operator's work intensity is greatly reduced, and theworking environment is better.

7.Favorable management:The use of a five-axis machining center is conducive to the mastery and management of production, creatingconditions for the automation of the production process.

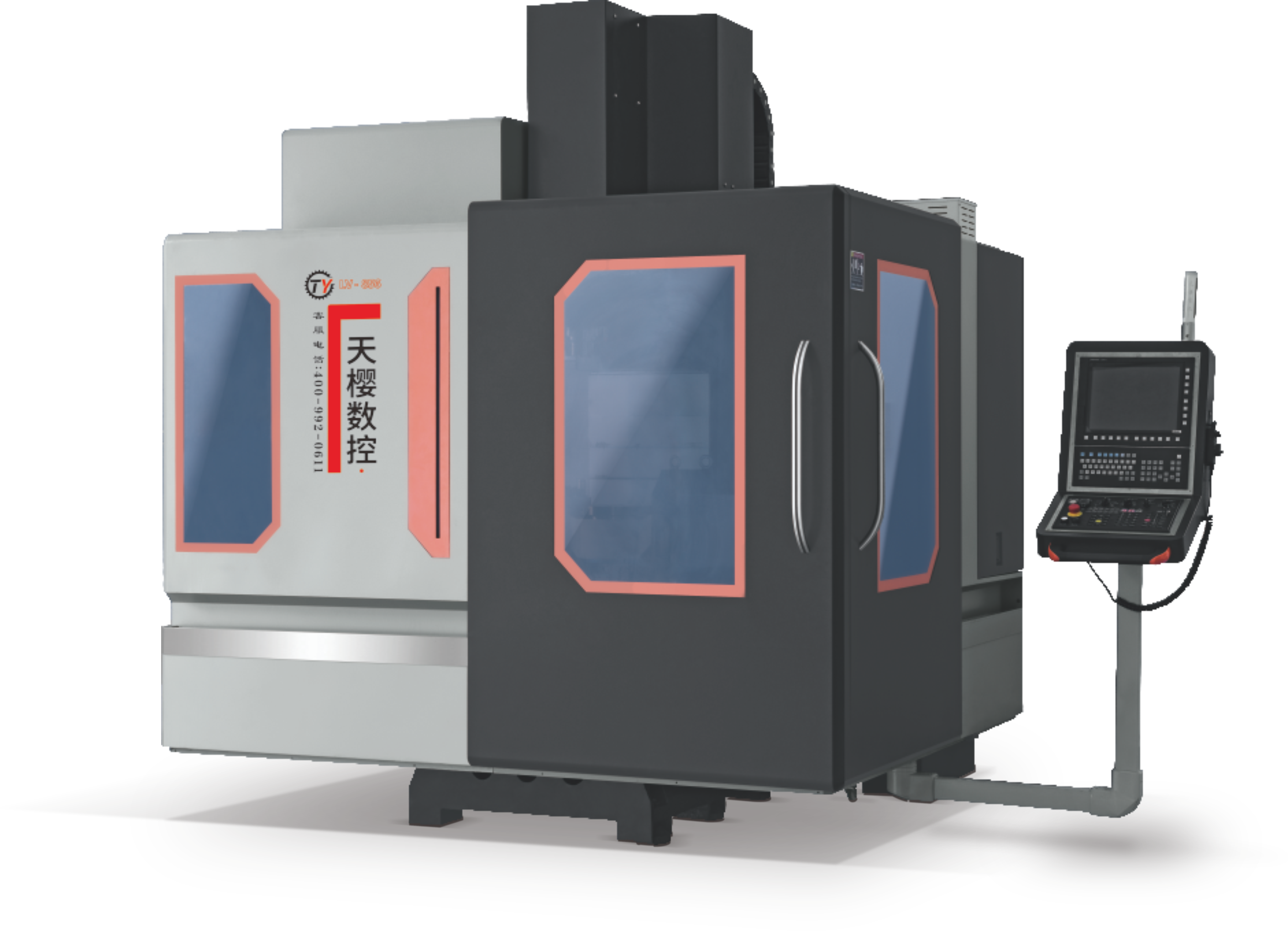

The machine body adopts computer CAD-aided design, with reasonable structure, strong stability and high rigidity.The overall casting is made of Meehanite cast iron, which has stronger shock absorption and shock absorption

performance and higher strength, and after secondary annealing stress elimination treatment, the machine tool precisionis more stable and durable.

The overall inclined bed casting structure is adopted to make the entire bed more rigid, more stable and durable.The universal spindle unit has high precision and easy maintenance, which provides the possibility of maintaining thelong-term precision of the whole machine.

This machine tool is especially suitable for large-scale and efficient processing of various high-precision, complex medium-sized parts in industries such as electronic cigarettes, military industry, automobiles, communications, and aerospace.

The machine tool base is made of resin sand casting, which has strong shock resistance, less deformation of the machine tool, and canstill maintain the accuracy and stability of the machine tool during heavy cutting.

The spindle motor adopts a variable frequency motor, and the speed can be changed in real time.

The spindle adopts a high-precision spindle and high-precision precision bearings, which are particularly suitable for processing high-hardness and large-cut parts.

At the same time, a large-stroke tail page is adopted, with stable speed, stable top force, and good use effect. The working slide is drivenby a precision-grade ball screw.

High power accuracy, fast running speed, strong rigidity, and faster servo-type tool change ensure the accuracy of the overall processing.

The milling machine tool perfectly combines the CNC lathe milling multi-sided machine tool, and has bothCNC turning and multi-sided forming chip cutting functions. It can complete multiple processes such asturning the outer circle, drilling, cutting and turning the multi-sided at one time.(The product has highconcentricity and one machine has multiple uses).

The milling machine tool adopts the bed and bed foot integrated sanding process, and uses imported rollerlinear rails and lead screws, so it has good shock resistance and strong cutting force.

The milling machine tool can realize spindle positioning according to different products, and can cut anypolygon processing (it can complete irregular shapes such as three-sided, four-sided, five-sided, six-sided,seven-sided, etc. at the same time) lf the milling machine tool does not use the turning polygon function, itcan also be used as a high-precision precision CNC lathe.

Processing of bulk products such as electronic cigarettes, hardware, watch cases, jewelry and stone inlays.

Multi-spindle processing machines have absolute advantages in simple products with small cutting volume, high speed,high efficiency and high precision products.

Various clamps can be designed according to customer needs so that the equipment can maximize its characteristics.Not having to change tools can save tool changing time and improve production efficiency.

The best bed structure design can withstand the inertia generated by high G, and is as solid as a rock and as stable asMount Tai.

The short nose spindle has excellent rigidity, which improves efficiency and reduces tool wear.The three-axis rapid displacement greatly shortens the processing time.

The high-stability tool change system reduces non-processing time.

The rear chip removal structure is adopted, which is convenient for cleaning waste chips and not easy to leak oil.All three axes are supported by high-rigidity linear rails, with fast speed and high precision.

The super-large column is stable, non-deformable and can move at a high speed of 48m/min.

The super-large span base adopts a solid point support structure, high-speed displacement, no vibration, and nodeformation.

The three-axis high-speed displacement reaches 48m/min, which is fast and saves processing time.

The low-inertia spindle design, the spindle direct drive, high stability, and the clamping arm tool magazine change toolsquickly and accurately.In addition to part processing,it is very suitable for drilling holes with smaller diameters.

The high-function AC spindle servo motor and the humanized conversational interface are used for easy operation.

High quality intelligent equipment and overall solutions

Provide scenario based solutions for industry clients

Exhibition event information release, industry technology sharing platform